The Importance Of Preventive Maintenance For Heavy-duty Trucks

Reliable trucks are the backbone of hauling and excavation work. When a truck is down, everything slows or stops. Crews are delayed, schedules get pushed back, and costs increase quickly. This is why preventive maintenance, often called PM, is not optional. It is a critical part of running a successful operation.

At Brooks Hauling, we operate heavy-duty trucks such as Kenworth W-900s (W-9s) and Kenworth T880s. These trucks are built to work hard every day, often under tough conditions and heavy loads. To keep them performing at a high level, we follow a strict and consistent preventive maintenance schedule. Staying ahead of maintenance allows us to stay dependable for our customers and avoid unnecessary downtime.

Preventive maintenance means servicing trucks before problems happen instead of reacting after a breakdown. Our PM services are based on mileage, engine hours, and how the truck is being used on the job. Routine maintenance includes oil and filter changes, fluid checks, brake inspections, tire inspections, suspension and steering checks, lighting repairs, and DOT-related items. These regular inspections help identify small issues early, before they turn into expensive repairs or roadside failures.

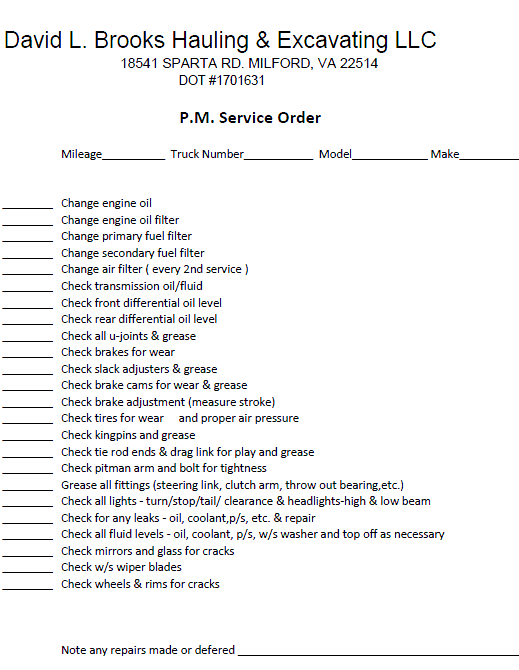

*Pictured is a small capture of our form we document with each P.M.

Keeping up with PM protects the truck itself. Kenworth W-9s and T880s are designed for longevity, but no truck can last without proper care. Regular maintenance helps extend the life of engines, transmissions, and other major components. Fixing a small leak, worn hose, or brake issue early costs far less than dealing with a major mechanical failure later. Preventive maintenance protects the investment made in each truck and helps maintain long-term value.

Downtime is one of the biggest expenses in the trucking and excavation industry. Breakdowns affect more than just repair bills. They can delay projects, interrupt customer schedules, and reduce productivity across an entire crew. At Brooks Hauling, we keep preventive maintenance on a tight schedule so our trucks are serviced before issues turn into emergencies. Planned maintenance allows us to keep more trucks on the road and avoid unexpected disruptions for our customers.

Safety is another major reason preventive maintenance matters. Heavy-duty trucks must be safe at all times, especially when operating on public roads and busy job sites. Through routine PM inspections, we closely monitor brakes, tires, steering, suspension, and lighting systems. This helps protect our drivers, our crews, and everyone sharing the road. It also keeps our fleet ready for DOT inspections and helps prevent violations, fines, or out-of-service orders.

Preventive maintenance also improves performance and fuel efficiency. Small maintenance issues, such as underinflated tires or dirty filters, can cause engines to work harder and burn more fuel. With regular PM, our Kenworth trucks run smoother, pull stronger, and operate more efficiently. Over time, these improvements help reduce operating costs and keep projects running on schedule.

At Brooks Hauling, preventive maintenance is planned, documented, and consistent. We follow strict service intervals and complete detailed inspections on every truck in our fleet. This disciplined approach allows us to catch problems early, schedule repairs efficiently, and keep our W-9s and T880s ready for demanding hauling and excavation work.

Preventive maintenance is not just an expense; it is a smart business decision. By keeping PM services on a tight schedule, Brooks Hauling delivers reliable equipment, safer operations, and dependable service. When customers choose Brooks Hauling, they are choosing a company that takes care of its trucks so every job gets done on time and without surprises.

Another key part of our preventive maintenance program is the strong relationships we maintain with our trusted vendors. Vendors such as NAPA, Chesapeake, Truck Pro, Truck Enterprises, and G&G play a critical role in keeping our fleet running safely and efficiently. Having reliable suppliers means we have quick access to quality parts, fluids, and components when our trucks need them. This helps reduce downtime, avoid delays, and ensure repairs are done right the first time.

These vendor partnerships allow Brooks Hauling to stay proactive with PM services instead of reactive. When parts are readily available and sourced from trusted companies, maintenance can stay on schedule and trucks can return to work faster. Our vendors understand the demands of heavy-duty equipment and help support the high standards we hold for our Kenworth W-9s and T880s. Their reliability, product knowledge, and responsiveness are a vital part of our preventive maintenance process and help us deliver consistent, dependable service to our customers.

Just as important to our preventive maintenance program are the skilled mechanics we work closely with every day. At Brooks Hauling, our mechanics are not brought in only when something breaks; they are a constant part of our PM process. We communicate regularly, review truck conditions, and stay ahead of service needs so maintenance is planned and efficient. This teamwork helps ensure our trucks are serviced on time and problems are addressed before they turn into breakdowns.

Our mechanics also play a key role in keeping detailed and accurate documentation of all PM services and repairs. Every inspection, service, and repair is tracked so nothing is missed and each truck’s maintenance history is clear and organized. This documentation helps keep our fleet DOT-compliant, supports long-term planning, and ensures accountability across our operation. Working closely with trusted mechanics allows Brooks Hauling to maintain a high standard of care for our Kenworth W-9s and T880s and deliver reliable equipment our customers can depend on.